- Blog

- News

THE EARLY YEARS

1904 – 1954

OVER 50 YEARS OF KEEPING AUSTRALIAN'S SAFE

A HISTORY BUILT ON SAFETY

One of the key reasons our customers tell us that they’ve chosen Linde over a competitor is safety. From outstanding operator visibility to industry leading ergonomics and the inherent anti roll back assurance of our hydrostatic drive system — our commitment to safety is second to none. Linde safety solutions have been developed to ensure they address the specific safety requirements of individual businesses. This includes reducing risks to the operator, personnel, equipment and warehouse. See below for a list of just some of the innovative intelligent assistance systems we’ve launched over the years — there’s far too many to fit into one page! If you want to find out more about how Linde can help improve safety in your business, contact us for a free consultation.

Contact UsFleetFOCUS

With Linde FleetFOCUS, you can review Workplace Health and Safety (WHS) compliance, cost efficiency and accountability via a web-based interface. This Australian built fleet management technology also enables engagement with Linde as a strategic partner, to help you assess important data in order to simplify and streamline your decision making.

Reverse Proximity Alarm An acoustic and visual warning that reduce accident potential in confined or obscured warehouse areas. It also automatically reduces the speed of the truck when an obstacle is detected, and can be programmed to respond to predetermined speed zones.

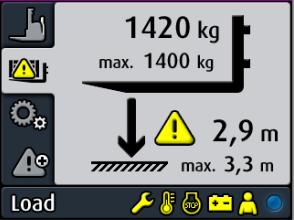

Linde Load Management Automatically calculates residual capacity based on the height of the forks and the weight they are carrying. Visual and audible warnings activate in safety-critical conditions, and speed reduction is applied in relation to the residual value, and as the steering angle increases.

Automatic travel speed control & Linde Curve Assist A speed assist system that provides automatic speed limitation, tailored to your business’ needs, throughout your site for both indoor and outdoor areas. A curve assist system that provides automatic, proportional speed adjustment when a truck is cornering, to create a safer working environment for the operator and nearby personnel.

Removal of the A-Pillar With an exciting new vehicle concept applied to our electric forklift trucks, we were able to introduce the Linde overhead tilt cylinders, which meant the A-pillar was no longer needed! This new design maximised the driver’s field of vision, thus improving safety.

Safety Pilot The system enables the operator to preselect their lift height, input lifting and lowering limits and have precise control at the touch of a button — helping to reduce operator error.

Dynamic Mast Control Automatically compensates and minimises mast oscillations and mast deflections through precise and seamless counter-movements of the reach carriage. This ensures smooth, simultaneous lift and reach movements for reach trucks.

BlueSpot A visual warning that projects a large, bright blue spot onto the floor several metres ahead of the vehicle in the direction of travel.

TruckSpot Building off the BlueSpot system, this projects a large 1.25 metre warning triangle several metres in front of a reversing forklift, providing an even more effective alert for nearby pedestrians and other forklift drivers.

Warning lines Clearly-visible bright lines are projected from the forklift onto the floor of the workspace around the truck, to clearly indicate hazardous areas for nearby pedestrians.

Stationary warning projector A compact, high performance LED spotlight that projects warning symbols from a fixed position, giving an visual warning to anyone in the path of an oncoming forklift.

LED stripes Lighting up white in the direction of travel and red in the opposite direction, they give the driver the best possible visibility and allow other vehicles/pedestrians to quickly and easily identify which direction the truck is travelling in.

VertiLight Illuminates a large working area thanks to its half-circular design with wide light band and seven LEDs. The LEDs distribute the light uniformly from the floor to the upper edge of the shelf, improving visibility of the shelf, load and forks. Thanks to the anti-glare LEDS, oncoming vehicles/pedestrians are less dazzled, and the driver is not irritated by reflective goods or truck interiors.

Linde Safety Guard Using transmitters on trucks, walls, racking and even carried on personnel themselves, the Linde Safety Guard systems creates warning zones to reduce the risk of accidents. If a pedestrian and a truck look likely to collide, both the industrial truck and the pedestrian are warned through a series of haptic, audio and visual signals. This system also works through walls or racking to alert workers coming around corners or through doors. Speed restriction zones can also be pre-defined and programmed so that the system automatically reduces the truck’s speed when in these zones. This is all made possible because the Linde Safety Guard system is able to detect marked objects or personnel with a position accuracy of ten centimetres, and warning zones are individually adjustable. This level of precision also minimises false alarms.

OUR GOAL: TO HELP OUR CUSTOMERS AVOID 100% OF ACCIDENTS IN INTRALOGISTICS

Linde’s ongoing dedication to developing intelligent safety technology, as well as technical innovations in our industrial trucks, provides integrated solutions that help our customers master the diverse challenges of modern, safe intralogistics. Thus, giving them the best outcomes for their business. We’ve kept you safe for over 100 years and we look forward to doing that for 100 more. If you want to find out more about how Linde can help improve safety in your business, contact us for a free consultation.

Contact Us