The K series man-up turret truck from Linde Material Handling enables high turnaround capacity for order picking and handling processes in high rack warehouses. The powerful drive trains make this possible, as the truck can move and lift at the same time. Also, even at high lift levels the speed remains high, and a high level of residual lift capacity is available.

Various assistance systems are available that help to navigate accurately through the warehouse or to avoid obstacles. In particular, the Linde System Control improves the process; depending on the version, the system adjusts the lift and travel speed according to the weight being transported. There are various versions of the mast, chassis, battery and cab for the very narrow aisle trucks, which can be combined according to usage requirements. There are around 10 million possible truck configurations.

Series 5231Linde K Very Narrow Aisle (VNA) Electric Forklift

The robust technology of the Linde K combination forklift ensures low service costs and a long service life.

The combination of the fork camera and crossline laser makes load handling much easier. The crossline laser helps to target the pallet and to pick it up precisely, and the fork camera provides optimum visibility for storage and retrieval at high rack levels.

The operator cab can be enhanced with several individual fittings, such as monitor, terminal scanner, storage facilities and writing support.

For the cab, the customer can choose between a front or divided operating panel. Both variants can be adjusted quickly for working in a standing or sitting position. The integrated full-colour display provides the operator with all the relevant information at a glance, from the speed of the forklift and the lifting height to the steering angle and the time of day.

If the operator leans on the barrier, it tilts outwards by 10cm. This enables the operator to reach the racking better, making order picking easier.

The equipment package includes a large rear-view mirror as well as lateral working lights to illuminate the working surroundings in the racking. There is also an optional ventilation system available to cool the operator when working at high lift levels in hot weather.

The ASC is an intelligent assistance system that detects unevenness between the left and right sides of the aisle, and automatically compensates for shocks and vibrations so the truck can achieve its maximum handling performance even on less than perfect floors.

The system provides improved throughput rates and increased safety. The LSC Standard basic version informs the operator of the residual load capacity depending upon the lift height. Other LSC versions automatically adapt the operating, lifting and auxiliary movements to the actual weight of the load being transported and the lift height.

This system combines all LSC functions and adds intelligent load stabilisation. When storing or retrieving loads, the system adjusts reach according to the current load weight and eliminates lateral mast oscillations. This enables loads to be moved faster and reduces the risk of damage to loads and racks.

The assistance system uses barcodes or RFID tags in the aisle to detect uneven floor surfaces, as well as obstacles on the racks or on the ceiling, and restricts truck functions such as operating and lifting speed, lift height or forks extension at these specific locations.

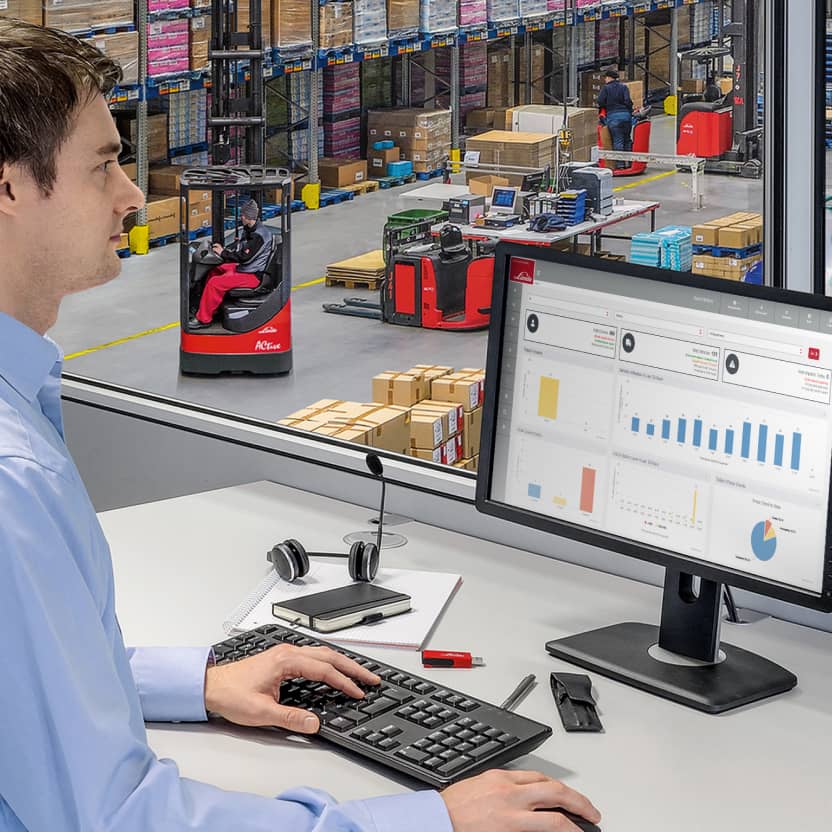

How and by whom are the individual forklift trucks used? What does the forklift truck usage data look like, and is each one roadworthy? Using a combination of software and hardware, the connect fleet management system provides all the answers.

The K-truck is available for cold store application. Amongst other things, the forklifts are operated with special hydraulic fluid and lubricants and receive a corrosion-proof coating. Additionally, there is the option to choose from a variety of enclosed, insulated cabs. A closed and heated cold store cabin provides comfortable working conditions.