- Blog

- News

Linde Material Handling has attended the Australian Logistics Council (ALC) and Australian Trucking Association (ATA) Supply Chain Safety Summit at Sydney's Hilton Hotel (16-17 September) to showcase its commitment to safety in the MHE space. Linde, which attended as both an exhibitor and sponsor of the event, also used the occasion to demonstrate its new Linde Safety GuardTM device.

The Safety Summit focused on building a strong safety community by bringing together representatives from every sector of the supply chain to share safety learnings and present practical safety solutions. Through presentations, interactive panel sessions, workshops and technology demonstrations, attendees were given a thorough insight into the measures being taken to manage a raft of safety issues across the supply chain - from Chain of Responsibility obligations to dealing with fatigue and mental health issues.

MHE Safety is one of the most important drivers for our organisation; it's at the heart of our engineering DNA.

Linde Material Handling's National Marketing Manager, Christine Nolland said “MHE Safety is one of the most important drivers for our organisation; it's at the heart of our engineering DNA. Forklift accident and fatality figures are just far too high and that's why Linde Material Handling is continually developing new safety innovations to assist in the prevention of accidents and fatalities.”

Linde has a long-term commitment to safety and technological innovation and has introduced a comprehensive range of safety features over the years as it seeks to minimise the injuries and fatalities involving forklifts. This encompasses a full suite of safety solutions that are either engineered into the forklifts or can be retrofitted as a business requires.

In any busy MHE environment there are always risks to the truck operators and warehouse staff, not to mention the handling equipment and warehouse structures. Any space around doors, exits, crossings and blind corners is potentially hazardous. So, at the core of Linde innovations is accident avoidance technology - to minimise and prevent accidents, injuries and collateral damage.

Innovations include the Linde Safety Pilot which displays a visual and acoustic warning when truck parameters are reaching their limit, as well an auto lift cut out to prevent overloading. A Reverse Proximity Alarm also features acoustic and visual warnings for the truck operator when reversing while with BlueSpotTM, a high-intensity, low-consumption LED light is projected onto the floor several metres in front of the truck to alert warehouse workers that there's a vehicle coming.

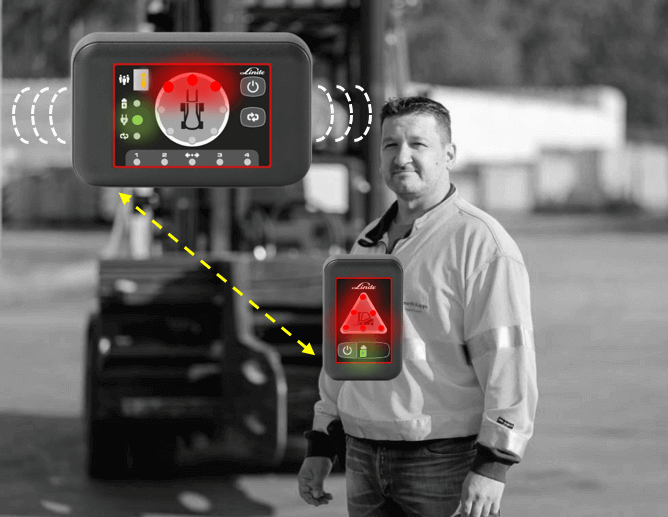

At the Supply Chain Safety Summit Linde Material Handling showcased its latest safety innovation: the Linde Safety GuardTM. In developing this cutting-edge technology Linde took into account many of the factors that result in accidents involving forklifts: unforeseen situations, routine, stress, distraction, impaired visibility, speed and forklift manoeuvrability. The goal was to create a monitored intelligent “safe zone” around both trucks and people. The solution: Portable Unit Proximity detection and collision avoidance assistance system. A system that alerts pedestrians and drivers of each other early - even through walls. The smart, modular design is quick and easy to install. A 12cm x 7.5cm unit is fixed to a truck while a portable unit is used for pedestrians to wear on their body.

Portable Unit Proximity detection and collision avoidance assistance system

While there are other assistance systems on the market, the problem with these systems is that they have a wide range, meaning everyone in the vicinity is alerted and there's sensory overload, so eventually the signals are no longer fully perceived. The smarts within the Linde Safety GuardTM however mean that a warning signal is only issued when there is real danger, with a position accuracy of 10cm. So, there are no annoying, frequent notifications. And for the warehouse workers, the technology allows them to “sense” the dangers, as the mobile device issues not only acoustic and visual alarms, but also vibrates. For the drivers, there is clarity too. A display shows not only how many people are in the warning zone but also from which direction they're approaching the truck.

We see a lot of value in partnering with key industry bodies and being a voice around the MHE industry where we can showcase to the ALC audience Linde's approach to MHE design innovation and safety.

Another big advantage of the Linde Safety GuardTM is that the signal is transmitted through shelves, walls and shutters* thanks to ultra-wideband technology in the 4GHz range, which means workers are warned of the approaching truck even when they can't see it. And thanks to the technology's flexibility, the time of warning can be adjusted to suit specific applications. Importantly, other networks such as W-LAN, Bluetooth or RFID are not affected.

Excessive speed is another issue in confined warehouse operations. Blind crossings, corners and areas where people frequently cross the driveway are all danger zones for collisions. The Linde Safety GuardTM allows for the creation of specially defined zones where speed can be automatically restricted. This involves marking out critical, high risk work zones and precisely adjusting - limiting -the speeds when trucks approach these defined zones.

Christine Nolland said “The Supply Chain Safety & Compliance Summit is a major industry event that Linde Material Handling is proud to support. It's a big opportunity for participants to get together and identify key issues around safety as well share solutions that provide better safety outcomes in the future. We're also proud to partner with the Australian Logistics Council as a National Sponsor. We see a lot of value in partnering with key industry bodies and being a voice around the MHE industry where we can showcase to the ALC audience Linde's approach to MHE design innovation and safety. We regard this valuable partnership highly and look forward to supporting the ALC for many years to come.”

*Valid for typical intralogistics facilities. Checked during customer consultation.