- Blog

- News

When it comes to operating forklift trucks, human error is the most common cause of accidents at work. Lack of knowledge or poor concentration on the part of drivers cause operating errors, resulting in trucks tipping over and causing very serious injuries, damage to loading equipment and operating equipment, and last but not least, massive disruptions to the logistics workflow. A unique electronic driver assistance system from Linde Material Handling, the Linde Safety Pilot, is now on hand to offer forklift safety support with these issues.

In line with the relevant accident prevention regulations set out by the employers’ liability insurance associations, industrial trucks must be operated in a manner that ensures that stability is maintained. For this reason, the forklift truck driver is ultimately responsible for ensuring that the load lifted on the fork arms does not exceed the approved load capacity, that the load centre of gravity is taken into account and that the maximum lift height is not exceeded. However, drivers are often faced with the challenge of balancing three unknown factors, whose values can only be roughly estimated.

The driver is not only shown the load centre of gravity; the load weight currently placed on the fork arms, the current lift height, the tilt angle of the fork arms and the maximum lift height up to which the load may be raised are also displayed.

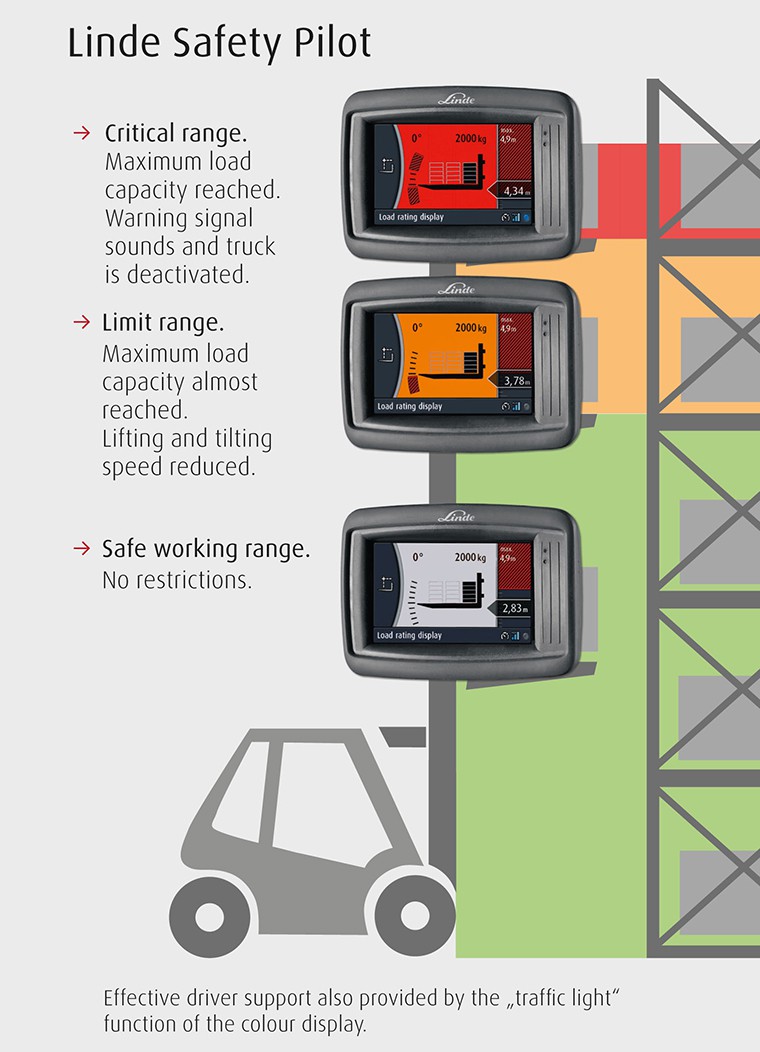

Without a detailed knowledge of the information specified by each manufacturer in the load capacity diagram, drivers may expose themselves and others to serious danger. The Linde Safety Pilot offers excellent support in this situation because in future drivers can simply look at the display mounted at eye level to find the answer to these three questions. The driver is not only shown the load centre of gravity; the load weight currently placed on the fork arms, the current lift height, the tilt angle of the fork arms and the maximum lift height up to which the load may be raised are also displayed. To help drivers quickly identify all of these values, the display features a clear design, it shows information in image format and the volume of numbers shown is kept to a minimum.

The Linde Safety Pilot is not just an indicating instrument though: If drivers are working in critical areas or if operating errors occur, they receive a visual and acoustic warning, and the truck control unit also actively intervenes and regulates the truck functions. For example, if a forklift truck driver wishes to place a load on the shelf and is approaching the load capacity limit, the lifting speed is reduced. If the forklift truck driver continues to lift the load and reaches the maximum load capacity, the truck is deactivated and safety-critical lifting and tilting functions are disabled. The driving speed is managed in the same way, according to the load, lift height, tilt angle and load centre of gravity distance. In other words, the speed of the truck is decreased continuously if the driver lifts the load while driving.

The technology behind the driver assistance system relies on sensors that measure data at different points on the truck and then forward this information to the truck control unit. An electronic load capacity diagram – the cornerstone of the Linde Safety Pilot system – is thus created.

Greater protection against operating errors is just one of the advantages of the innovative Linde Safety Pilot system. The system also provides various comfort features that assist drivers with their work and offers them significant added value. The sub-menus detailed below can be called up via a rotary push-button mounted in the armrest underneath the operating lever:

The introduction of the Linde Safety Pilot system is the culmination of many years of development and testing. “Although electronic safety assistance systems like ESC (Electronic Stability Control) are now part of the standard equipment of many passenger vehicles, a solution of this nature cannot be applied in exactly the same format to trucks. Appropriately adapting the solution requires special technical expertise due to greater variance between the load capacity classes, tyres, masts and load centres of gravity. This is why we are proud to offer our customers an assistance system tailored to the needs of the truck in the form of the Linde Safety Pilot system. This solution will enable our customers to operate their trucks in a much safer and more productive manner while also making forklift trucks more comfortable and easier to drive”, says Harald Will, Chief Technology Officer (CTO) at Linde MH.

The Linde Safety Pilot system will initially be available for the Linde E20 to E50 electric forklift trucks with load capacities of 2.0–5.0 tonnes. During the course of this year, the system will also be available for the Linde E16 to E20 electric forklift trucks with load capacities of 1.6–2.0 tonnes.

For more information on how Linde’s Safety Pilot system can help your business, contact Linde Material Handling today.