- Blog

- Customers

Until 18 months ago Martin Morales had no direct experience of Linde forklifts, but had absorbed hearsay about the German forklift brand. “If you mentioned Linde to me, my first thoughts were ‘equipment with a reputation for quality, but what about the cost’,” he said. Martin, who is Operations Manager NSW, for pallet and returnable packaging solutions provider Loscam Australia Pty Ltd, no longer holds those views. In fact he now oversees a fleet of seven Linde 393 Series 3.0 tonne forklifts at Loscam’s Wetherill Park operation in south western Sydney. LOSCAM provides returnable packaging solutions and equipment used to store and move products through some Australia’s largest supply chains.

Linde told us to expect a 30 per cent fuel saving with their truck and that was easily confirmed by the tests.

“Forklifts are particularly important to our business, Martin said. “We carry out 40,000 pallet movements per day in a virtually nonstop process. We also handle plastic pallets, IBCs, GPaks, retail ready merchandising units and produce bins. Previously we had other traditional technology forklift brands, but we decided to take on a Linde rental forklift and that gave us over a year of valuable experience with its productivity, after we experienced transmission problems with other brands.

“The nature of our business puts great pressure on our forklifts,” Martin said. “Day in and day out we are loading and unloading empty pallets, 40 at a time from customers’ trucks. Quite often we have to square up the stacks before we load them and that has led to transmission problems. We thought Linde’s hydrostatic transmission might just be a better solution for our application."

“Six of our seven forks are twin-tyne, so with each load of 40 pallets we raise the tynes out of the way and use the forklift mast just to square the pallets up so that they load neatly onto the truck.”

When the Linde trial forklift arrived Martin Morales was unsure it could provide a fair comparison with his existing forks. Linde were so confident of their product’s abilities in a tough work environment they had delivered a 13 year old forklift for the trial. From the outset the Linde proved clearly superior, not just in performance but also in gas usage.

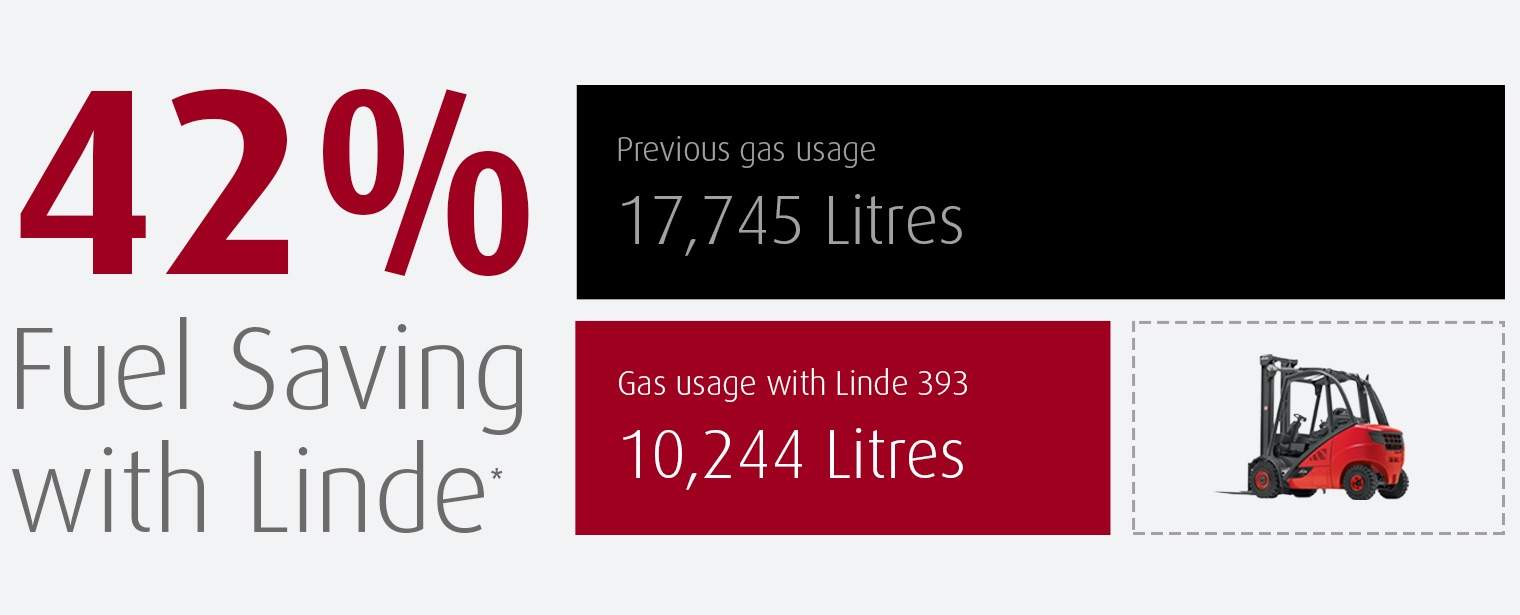

To confirm the results Linde supplied a gas consumption meter which was fitted to the trial truck for a week and then swapped over to one of Loscam’s two or three year old other brand forklifts performing the same work.

“Linde told us to expect a 30 per cent fuel saving with their truck and that was easily confirmed by the tests,” he said. “Linde also told us to expect even better fuel savings with a new truck. There I was with a 13 year old Linde forklift, and four other forklifts which were all about two years old. The Linde was easily the best of them.

“All of the big players were involved in the tender process but it wasn’t just a matter of comparing monthly rental and gas costs,” he said. "Safety also came into the equation prominently and there were many other factors we examined.”

For several months Loscam had been trialling movement sensors and other forklift safety options. The company had seen Linde’s BlueSpot system and liked the idea but the Loscam safety focus was such that it looked for additional measures. The answer came when Linde introduced Ezetech Solutions’ collision avoidance system, a sophisticated combination of sensing, control, operator alert and braking modules which work together to mitigate risk of collision with pedestrians and objects. The system’s state-of-the-art electronics make it difficult to fit to some forklift brands with rudimentary electronics. Linde forklifts incorporate a future-proofed CANBUS network which makes addition of the Ezetech Solutions’ collision avoidance system and implementation of all its abilities straightforward.

“All the other systems we had trialled just weren’t going to work here where we have lots of pedestrian traffic,” Martin Morales said. “On the other hand Linde introduced us to a system which not only detects potential collisions, but warns the operator and can slow the truck."

“Despite the great fuel cost results it was a combination of these safety measures, FleetFOCUS fleet management and the level of support offered which got Linde over the line. Our workplace health and safety people were determined to improve our operating safety and it was Linde who introduced us to a solution which really works."

“When we examined the monthly rental costs for seven of the Linde three tonne gas forklifts, with the safety advantages, productivity, support and the fuel and tyre wear savings, we actually found it would be less expensive to run Lindes than any of the other brands we were considering. It was really a no brainer.”

Because the Lindes are so good and because I had a 13 year old Linde which was the best truck on my fleet we signed up for five years instead of the three year term we have previously gone with.

Martin Morales said Loscam had used various fleet management systems at different sites previously, but the Linde FleetFOCUS system offered more.

“You can really drill down into it to extract exactly the information you need," he said. "Even the pre-start operator checklist questions are customisable. With three months experience we are now planning to change a couple of the questions, so that ability is really handy,” he said.

“I like the fact we can just send an email to customer service at Linde for something to be actioned. You don’t have to wait to make contact with a rep. I had a real problem in that regard with a previous forklift supplier. Comparing that with Linde’s performance is just chalk and cheese.

“We replaced two forklift transmissions during the previous three year lease agreement and the cost was something we had to bear. Actually that had been going on over a number of years, but now with the switch to Linde and the hydrostatic transmission that should be behind us.

"Because the Lindes are so good and because I had a 13 year old Linde which was the best truck on my fleet we signed up for five years instead of the three year term we have previously gone with. Now if I tried to bring in a forklift with the traditional transmission none of the operators would go anywhere near it. They really appreciate the Linde hydrostatic transmission.”

The productivity improvements and shorter cycle times made possible by adopting Linde forklifts with their hydrostatic transmission have also made a significant difference for Loscam, allowing the company to load customer trucks rapidly at a space-constrained site.

Now if I tried to bring in a forklift with the traditional transmission none of the operators would go anywhere near it. They really appreciate the Linde hydrostatic transmission.

In the two months before switching to the same number of Linde forklifts to perform the same work, Loscam’s Wetherill Park facility used 4.8 and 4.2 tonnes of LPG. In the two months from the arrival of the Linde forklifts it used only 2.6 tonnes each month. Martin Morales is now very happy Loscam took that opportunity to trial a 13 year old Linde forklift.