- Blog

- News

Linde Power Solutions has achieved one of its key aims just a year after entering the market. The newest business unit of Linde Material Handling has filled more than a thousand orders and proved its single-source credentials to leading operators of battery electric equipment throughout Australia.

Linde Power Solutions was established in 2013 to allow equipment users to tap the best hardware, experience, and consultancy services for their electric forklift or electric warehouse equipment investment. It supplies replacement batteries, chargers, battery handling equipment and specialised consulting expertise in battery room design and safe operation to operators of Linde and all other brands. "There are so many choices when you are operating battery electric equipment and it is easy to make the wrong one when replacing a battery or a charger or setting up a battery room," Linde Managing Director Carl Smith said. "These are not decisions which people have to make very often so inexperience can lead to costly mistakes. We wanted to provide a single source where customers could go with confidence, knowing that their needs would be met with quality, price competitive equipment backed by expert advice. Initially our intention was to provide this service only for operators of Linde equipment, but it became clear that there is a wide demand from users of other brands who would otherwise be left to make difficult choices on their own. The market’s reaction has proved that to be the case."

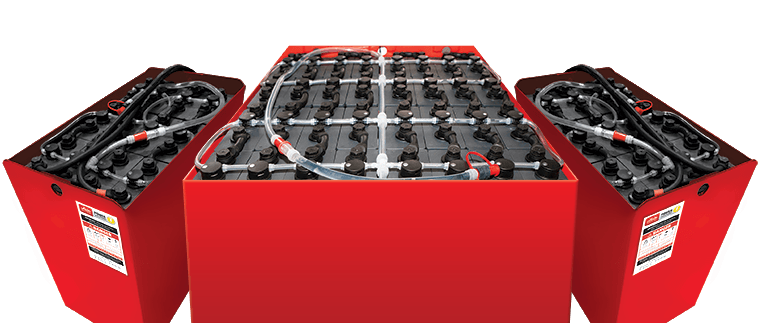

Linde Power Solutions has partnered with some of the world’s most respected brands to source the batteries and chargers it sells with market-leading factory guarantees.

Its battery supplier, Midac, is one of the leading European manufacturers of industrial motive power batteries. Midac cells and batteries can be fitted with a wide range of accessories to achieve maximum performances and reliable use. The Italian manufacturer’s credentials are underscored by its factory’s use of clean energy produced by a rooftop photovoltaic system for the production of batteries and accumulators, avoiding the emission of nearly 1,000 tonnes of CO2 each year. Italy is also the source of Linde Power Solutions’ advanced chargers. The Mori brand has established a reputation for innovation flowing from intensive research and development. Mori not only designs and assembles complete chargers, it also designs and produces the majority of their components. The company’s chargers are known for their flexibility which allows set-up without the dip-switches which confuse many users and can lead to problems. Mori Power-Switch switch mode chargers available through Linde Power Solutions are expertly set up and configured at Linde before shipping, utilising an advanced PC programmer.

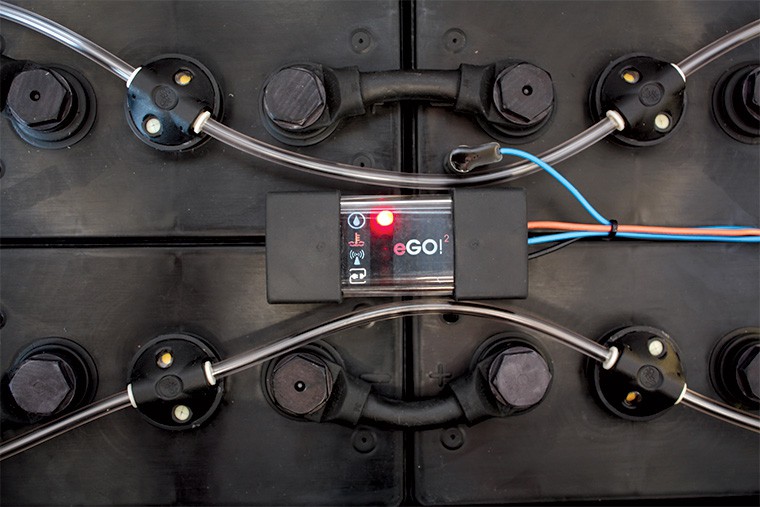

To ensure the potential to identify life-shortening battery health issues before they become serious, Linde Power Solutions also specifies high-tech diagnostic sensors to be fitted at the time of assembly. Customers have the option to request activation of a remote monitoring system to watch over their batteries throughout their working life. These eGO! battery monitor sensors are sourced from Philadelphia Scientific, another leader in its field. They are designed with demanding materials handling environments in mind, and can record everything important about the life history of a battery. The battery mounted eGO unit continuously monitors the cycles, opportunity charging, voltage, electrolyte level and temperature of the battery. Bright LED’s indicate the electrolyte level and temperature status of the battery, to assist correct maintenance. Consulting services and site audits available through Linde Power Solutions enable users to maximise the benefits of this leading edge battery, charger and monitor technology.

For more information on what Linde Power Solutions can do for your battery electric equipment, contact Linde Material Handling today.